Forty years of excellence is part of the legacy of Roland DG, a global company whose reputation has been built on quality wide-format inkjet printers, engravers, photo impact printers, and computer numerical control milling machines.

Personally, I know them for their music-related products, which I have always added to my collection because of their superior craftsmanship in synthesizers, digital pianos, electronic drum systems, and DJ gear. Their attention to detail and value have crossed over into their U.S.-based dental division, Roland DGA.

Each generation of Roland dental-focused products offers more treatment options and opportunities to create quality dental restorations. Most recently, the company upgraded its chairside milling solution to increase clinicians' restorative capabilities and produce lab-quality restorations.

I spoke with Lisa Aguirre, the dental marketing manager at Roland DGA Corporation, about the upgrades to the DGShape DWX-43W Chairside Milling Solution.

The DGShape DWX-43W Wet Milling Solution. Image courtesy of Roland DGA Corporation.

The DGShape DWX-43W Wet Milling Solution. Image courtesy of Roland DGA Corporation.

Dr. Shuman: What exciting news do you have to share about the DWX-43W Wet Milling Solution?

Aguirre: We recently announced this upgrade to our existing, best-selling chairside milling solution. We have made some great improvements to it in efficiency, greater return on investment, and features that decrease operating and ownership costs.

Dr. Shuman: What are some of the most valuable upgrades, in your opinion?

Lisa Aguirre.

Lisa Aguirre.

Aguirre: One of the biggest benefits is the filter-free innovation. Traditionally, wet mills have some type of filter, and obviously, there are costs involved with each filter replacement. With the new technology, omitting the need for filters decreases operating costs by about 20%. In addition to not having to pay for inventory filters, this unit also does not need as much maintenance. Its automatic coolant jet optimization with a draining cycle reduces routine mill maintenance by 50%. As long as the machine is on, even 24 hours a day, the unit will automatically perform this task. This minimizes the amount of actual daily and weekly maintenance that's required, freeing the staff for more important tasks.

Dr. Shuman: I hear there are some freebies that are very valuable with this upgrade. Tell me more about those.

Aguirre: Users receive the new DGShape CAM-dedicated software included with the purchase. This decreases milling times by up to 20% while increasing milling efficiency and predictability. To make it even faster, the “quick mill” option lets the user select frequently used materials, which makes starting the milling process even easier.

Another amazing upgrade to this unit is the built-in expanded capabilities. With the previous 42W models, to mill titanium abutments, the clinician needed an AK-1 abutment accessory kit. The user had to replace the existing material adapter fixture inside the machine with the AK-1-compatible material adapter. The new internal design for the DWX-43W includes automatic compatibility, so it reduces the need for the kit. All the user has to do is buy the material adapter, which corresponds to whatever pre-mill blanks they are using. The new built-in capabilities save users $1,000 on the purchase of the accessory kit.

The DWX-43W upgraded solution also comes with (at no extra charge) 15-DGShape authentic wet-milling tools, as well as added accessories, which is a $1,200 value.

Added in, the tooling for milling custom titanium abutments is a new roughing tool, the DGShape ZTR-150D, that facilitates 20% faster milling of titanium custom abutments compared to the previous ZTB-150D tool. (The new tool is not compatible to use with previous DWX-42W series milling solutions.) Another exciting added-value accessory is the ZV-42W, a six-pin adapter that, instead of milling three units at a time, allows for milling up to six units simultaneously for traditional restorations.

Dr. Lou Shuman.

Dr. Lou Shuman.

Dr. Shuman: Can you tell me more about how this chairside milling solution saves time for the practitioner?

Aguirre: Clinicians don’t have to hang around the office to get the job done. The device-monitoring features, with DGShape’s proprietary V-panel and DGShape Cloud software, are included at no cost, giving the owner the freedom to leave the office while knowing that the mill will have their restorations ready on schedule. Users can monitor their DGShape milling solutions from anywhere on any device.

Dr. Shuman: Do users have to change their favorite software to use this chairside mill?

Aguirre: Definitely not. DGShape’s open architecture ecosystem allows users to use their own choice of scanner, CAD software, and restorative materials.

Dr. Shuman: Are there any specific materials that would be particularly helpful with this chairside milling solution?

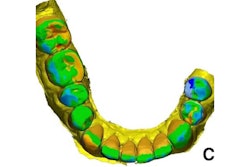

Aguirre: To produce the most restorative strength and aesthetics, we recommend Chairside Zirconia, a fully sintered CAD/CAM milling block designed for DGShape DWX wet milling solutions. Same-day zirconia restorations can be produced at full strength, with no sintering or firing prior to seating. Using the right material minimizes the finishing time for same-day restorations and can increase production dollars per hour by up to 20%. Chairside Zirconia is perfectly suited for single-unit dental lab rush cases and chairside restorations. Another material, Amber Mill Direct, is a pre-crystalized, lithium disilicate-based, glass ceramic CAD/CAM milling block designed for wet milling that requires no crystallization, and no ceramic oven or firing is required. Both of these materials are multilayered gradients for optimal aesthetics.

The DWX-43W is also compatible with traditional lithium disilicates, glass ceramics, polymethyl methacrylate (PMMA), hybrid ceramics, composite resins, pre-mill titanium CAD/CAM blanks from Medentika®, DESS®, and GeoMedi®, and more.

Dr. Shuman: What is the price point on the DWX-43W?

Aguirre: Compared with other chairside milling on the market, the most trusted name in the dental lab industry, Roland DGA’s DGShape provides lab-quality restorations and tremendous value all for about $30,000. And if you figure in the free 15 high-quality DGShape wet milling tools, the six-pin material adapter (#ZV-42W), and the DGShape CAM-dedicated software, the savings are about $5,600. That makes a big difference.

Dr. Lou Shuman is the president and CEO of Cellerant Consulting Group and is professionally known for his expertise in Internet strategy, strategic relations, emerging technologies, digital marketing methods, and operational practice management.

The comments and observations expressed herein do not necessarily reflect the opinions of DrBicuspid.com, nor should they be construed as an endorsement or admonishment of any particular idea, vendor, or organization.