A clever use of CAD/CAM technology brought a smile to a patient with primordial dwarfism. Researchers from Texas A&M University described their novel technique for creating implant-supported dentures in a study published on April 28 in the Journal of Prosthetic Dentistry.

Primordial dwarfism describes a group of disorders in which a person experiences delayed growth, resulting in small body size. People with this condition also experience a number of dental manifestations, including short roots, enamel defects, delayed tooth eruption, and missing teeth.

In the described case, the patient had limited mouth opening that made it difficult to obtain conventional implant impressions. The authors instead used cone-beam computed tomography (CBCT) with radiopaque markers to transfer the positions of the implants to a virtual cast.

Digitalized maxillary interim complete denture from an intraoral scan. All images published in the Journal of Prosthetic Dentistry, April 28, 2021, Amirali Zandinejad, Hui Liang, Nicole A. Fisher, Cosio, Marta Revilla-León, "Fabrication of a complete-arch implant-supported fixed interim prosthesis by using a cone beam computed tomography digital scan for a patient with primordial dwarfism: A dental technique," Copyright Elsevier 2021.

Digitalized maxillary interim complete denture from an intraoral scan. All images published in the Journal of Prosthetic Dentistry, April 28, 2021, Amirali Zandinejad, Hui Liang, Nicole A. Fisher, Cosio, Marta Revilla-León, "Fabrication of a complete-arch implant-supported fixed interim prosthesis by using a cone beam computed tomography digital scan for a patient with primordial dwarfism: A dental technique," Copyright Elsevier 2021."The described technique provided an alternative digitizing procedure to obtain a virtual implant definitive cast, which facilitated the implant-supported interim prosthesis design and manufacturing," wrote the group, led by Dr. Amirali Zandinejad, an associate professor at the Texas A&M University College of Dentistry in Dallas.

The patient had interim complete dentures that were esthetically and phonetically acceptable, but she had concerns about retention and stability. She opted for maxillary and mandibular complete-arch, implant-supported prostheses.

Implants were placed at the patient's left and right premolar and lateral incisors. But because her mouth prevented the authors from taking a conventional impression, they opted for a different technique to map the implant positions.

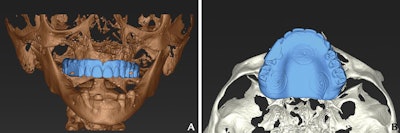

CBCT scan aligned with maxillary interim complete denture in (A) frontal view and (B) occlusal view.

CBCT scan aligned with maxillary interim complete denture in (A) frontal view and (B) occlusal view.At the patient's first appointment, they removed the abutments' protective caps and placed five radiopaque markers on the maxillary interim complete denture. They then used an intraoral scanner to digitize the denture.

Next, the authors took a CBCT scan of the patient with the denture inserted but without tooth contact. After the scan, they created a stone cast impression of the denture before returning it to the patient.

Following the appointment, they digitized the stone cast with a lab scanner and imported the files into a dental CAD software program. In the program, they aligned the denture scan with the CBCT scan using the radiographic markers to align the data. This allowed the team to place maxillary implants with corresponding abutments in the same location as the existing implants.

The authors then exported the denture and implant positions in just one file with combined data. After creating a virtual design file in a second CAD program, they manufactured a maxillary screw-retained interim prosthesis from a multilayer polymethyl methacrylate (PMMA) interim material and milling machine.

Patient's smile while wearing her new maxillary implant-supported interim prosthesis.

Patient's smile while wearing her new maxillary implant-supported interim prosthesis.The patient received the new prosthesis at her second appointment, and the authors noted that clinical and radiographic outcomes were acceptable. However, they cautioned that more studies are needed to evaluate the accuracy of their technique.