Dear CAD/CAM Insider,

3D printing open impression trays could save you time and money, according to the findings of a new study in the Journal of Prosthetic Dentistry.

Researchers from China compared the accuracy and feasibility of using a digital dentistry workflow with a conventional technique to fabricate custom open tray impressions. Discover just how much time and money the CAD/CAM workflow saved clinicians in this edition's Insider Exclusive.

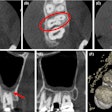

Also new in the CAD/CAM Community, researchers created a CAD-based method that could reduce radiation exposure before craniomaxillofacial surgeries. The technique uses a digital dental scan and could reduce the need for additional cone-beam computed tomography (CT) scans before navigation-guided procedures.

Speaking of innovative workflows, researchers described a method to quickly and easily duplicate dentures using a general intraoral scanner, free CAD software, and a 3D printer or milling machine. The innovative dentists behind the workflow said it could reduce cost and treatment time for patients.

When it comes to taking an intraoral scan, color matters, according to the findings of a recent study in the Journal of Prosthodontics. Clinicians had the best luck when using a blue-light scan setting and keeping the overhead room lights on.

Last but not least, researchers used 3D printing and CT imaging to get a better understanding of a prehistoric shark's unusual jaw. To trap its dinner, the shark's lower jaw and teeth would rotate inward, capturing and holding prey. Yikes!

Thanks for being a member of the CAD/CAM Community. I'm looking forward to sharing exciting, innovative updates from the upcoming Chicago Dental Society Midwinter Meeting and beyond.