Brackets made from clear plastic polymer used in dental correction orthodontics have produced very good results in recent years, especially in relation to the improved aesthetics when compared with metal brackets, but they do present certain problems of wear and tear within the mouth.

Now a collaboration between researchers from Universidad Carlos III de Madrid (UC3M) and the company CEOSA-Euroortodoncia is using nanoparticles to address the problem.

"We were estimating the friction between teeth and the brackets, and it occurred to us that nanotechnology might be of use to help us resolve this issue," remarked Juan Baselga, head of the UC3M Polymers and Composite Group, in a university news release.

The solution they came up with is to use very hard alumina nanoparticles and spread them evenly in the polysulfone, the polymer mold that Euroortodoncia uses in the industrial production of the brackets. This process, patented by the company and the UC3M researchers, has produced a new material that increases mechanical as well as friction resistance, thereby maintaining the brackets' transparency.

"We have been able to develop a more rigid material with this technology which has a clearly improved friction resistance, thus helping to withstand the wear and tear produced by the teeth or by chewing, Baselga explained. In addition, it is biocompatible and complies with European requirements for products that are in contact with food.

These new types of materials -- known as nano-reinforced plastics -- have applications in diverse areas of industry, according to the researchers. In particular, polysulfone is of interest in the biohealth field because of its biocompatibility in the development of medical-surgical equipment, where it is of the essence to improve rigidity and friction resistance. Furthermore, it has potential applications in the auto industry and the area of safety, such as the development of a new visor for firefighters.

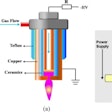

This innovation allows nanoparticles to be incorporated and evenly dispersed in a polymer mold in a very low proportion. After this process that is based on green chemical techniques is carried out by UC3M researchers, the particles, which are now dispersed in the polymer through microextrusion and microinjection techniques, are then mixed to produce the final piece.

"We measure out the plastic since the minimum that a normal machine can inject is 15 grams, whereas our pieces weigh 0.06 grams ... it would be akin to injecting insulin with a horse syringe," explained the company director, Alberto Cervera. "And with the technology we are using, microextrusion and microinjection, we are able to control these minuscule quantities of material with the utmost precision."