A new study demonstrates a method to create a master cast for multiple implant treatment planning using digital technologies. Using digital technologies can ultimately save time and money, the study authors noted.

“The results show a significant cost savings in attachments, as well as an increase in the quality of reproduction and accuracy of the master cast.”

The PLOS One study detailed a six-step method to creating the dental cast, which includes using an intraoral scanner and CAD/CAM. The Spanish researchers also showed the cost-effectiveness of their method compared with creating casts with traditional, analog technologies (PLOS One, December 22, 2015).

"Compared with the conventional master cast, the results show a significant cost savings in attachments, as well as an increase in the quality of reproduction and accuracy of the master cast, with the consequent reduction in the number of patient consultation and visits," the authors wrote.

6 steps

Creating master casts for multiple implant treatment planning traditionally requires a tedious and long process by dentists and dental technicians, according to lead researcher Luis Romero, PhD, and colleagues. The authors instead sought to create a digital cast-creation process that was faster, less expensive, and more accurate than analog cast creation.

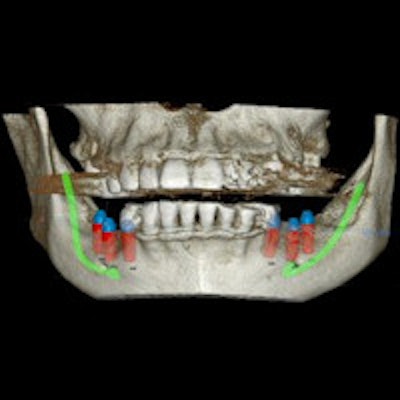

They came up with the following six-step process to digitally create a master dental cast.

The researchers specifically noted to use photogrammetry, a technology in intraoral scanners, because it has a high enough accuracy for implant planning.

"The 3D scanners' accuracy depends on photogrammetry, technology which is considered as the most accurate in noncontact three-dimensional measurement," Romero and colleagues wrote. "The advantage of the methodology proposed in this study is based on the use of an intraoral scanner that uses photogrammetry, enabling scans of all patient implants without alignment by overlapping the various scans of each implant."

The researchers also noted that their master cast included holes with nuts at the base of each implant. The nuts allowed them to adjust as necessary and perform tests on the master cast.

"The reason why these nuts are incorporated is that 3D printing still lacks (or the cost is too high) the detail of a threaded M2 fillet with sufficient quality and robust enough to withstand the tests to which the master cast must be submitted during the process," they explained.

Digital models make economic sense

In addition to outlining a step-by-step process for creating a digital master cast, the researchers also looked at the cost of creating a digital master cast versus an analog one. They found that the digitally created casts took far less time and cost less than traditional dental casts.

| Criteria | Conventional master cast | Digital master cast with analogs | Digital master cast without analogs |

| Average time to obtain final prosthesis | 10-12 weeks | 2-4 weeks | 2-4 weeks |

| Total process cost (on a scale of 1-5, with 5 as most expensive) | 5 | 4 | 3 |

| Final accuracy of prosthesis | 0.1 - 1 mm | 0.01 - 0.016 mm | 0.01 - 0.016 mm |

| Master cast functionality (on a scale of 1-5, with 5 as most functional) | 2 | 5 | 5 |

"The manufacture of the master cast using digital process affects fewer activities in a laboratory and a reduction of overall times of the whole process," the researchers explained. "In addition, the time employed for the final adjustment of the prosthesis in the mouth is much lower with digital methodology."

Romero and colleagues also performed more than 25 tests using the digitally created casts on edentulous and partially edentulous patients. The supplemental results, which were included as an appendix to the PLOS One study, found that the digital master casts did live up to expectations.

"After the study of tests in edentulous and partially edentulous patients of different dental clinics, it is confirmed that the use of master model built digitally (with the right materials) for the preparation of different prosthesis types, ensures a decrease in costs and an increased precision in the mouth, and therefore, the patient's satisfaction," the authors concluded.