Implant manufacturers usually provide congruent osteotomes for patients who have spongy bone structures. However, these instruments must be inserted with controlled hammer strokes, which is unpleasant for most patients, and there are gentler options.

One such alternative is the MaxilloPrep Spread-Condense system (Kit 4596) from Komet (figure 1). Developed in conjunction with Dr. Stefan Neumeyer of Eschlkam, Germany, the MaxilloPrep Spread-Condense system was designed for bone spreading and condensation by means of titanium Spread-Condense screws.

Figure 1: The MaxilloPrep Spread-Condense system. All images courtesy of Komet.

Figure 1: The MaxilloPrep Spread-Condense system. All images courtesy of Komet.

Bone spreading treatments are used because of a narrow bone structure and insufficient space to place an implant. In my experience, the Komet instruments allow practitioners to provide a gentler treatment.

Using a hand wrench, Spread-Condense screws are inserted into a small pilot hole, prepared using a Komet stainless steel drill (210L16). The screws are then screwed in and out in ascending order until the required target size is reached, ensuring optimum stability of the subsequently inserted implant. The condensed bone bed provides improved stability during the insertion of all commonly used implants.

The system's screws are available in five sizes; sizes 4 and 5 also come with a triangular cross-section for condensation and expansion of extremely hard bones. Because all screws are made of pure titanium, they are designed for multiple uses.

Thanks to the depth marking placed in intervals of 2 mm, penetration depths can be visually controlled at all times, starting at 8 mm from the tip of the screws. Depth markings are easily recognizable because the surface color alternates between light and dark every 2 mm. The screw's round end safely protects from inadvertent perforations, and a precise multistart thread and nonsymmetrical thread flanks allow easy penetration. The screw's shape is initially cylindrical along the first 5 mm, then turning into a tapered shape up to a total length of 15 mm.

Clinical case study

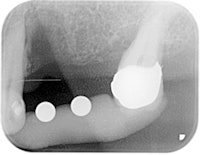

Figure 2: Radiograph with measuring balls.

Figure 2: Radiograph with measuring balls.

Because of a severe endodontic/periodontal lesion, tooth 24 of a 59-year-old woman was beyond saving. A radiograph with measuring balls was taken three months after extraction, illustrating the extent of the preceding osteolytic process (figure 2).

Implantation was carried out six months after the tooth's extraction. After a cut was made -- slightly offset in palatine direction -- and the alveolar ridge was exposed (creating a mucoperiosteal flap), a pilot hole was drilled with the kit's small pilot drill. This was done in accordance with the planned preparation length in the region of teeth 24 and 25. The optimum speed was 800 rpm in the green contra-angle handpiece, and the site was cooled using externally supplied saline solution. If required, the site can be previously marked with a sharp triangular centering bur, which is also included in the kit.

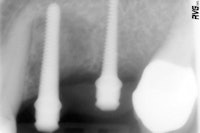

Figure 3 (top): An overview of the system's components, including the manual wrench.Figure 4 (bottom): Radiograph to control the proper position of the Spread-Condense screws.

Figure 3 (top): An overview of the system's components, including the manual wrench.Figure 4 (bottom): Radiograph to control the proper position of the Spread-Condense screws.

Figure 4 (bottom): Radiograph to control the proper position of the Spread-Condense screws.

The Spread-Condense screws can be screwed in with intuition using the hand wrench (figure 3). The laser-etched depth markings are clearly visible during clinical use. Achieved by mechanical clamping, the screw's secure fit allowed for the radiographs to determine the position and the depth without inadvertent aspiration (figure 4).

Figure 5 (top): The Spread-Condense screw is screwed in by means of the hand wrench.

Figure 5 (top): The Spread-Condense screw is screwed in by means of the hand wrench.

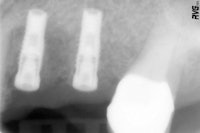

Figure 6 (bottom): Radiograph to control the implants after implantation.

Figure 6 (bottom): Radiograph to control the implants after implantation.

The Spread-Condense screws were inserted in ascending order up to size 3 with the ratchet. Alternatively, a mechanical wrench was used for rotary insertion; however, this was preceded by the manual wrench (figure 5). Two Wital implants (Wieland Dental) were inserted with primary stability without further chip-producing preparation (figure 6). The treatment concluded with the augmentation of the autologous vestibular bone in tooth 24 and the filling of the defect bone up to the terminal molar.

As demonstrated in this example, Komet's MaxilloPrep Spread-Condense system is a minimally invasive alternative to the traditional hammer-plus-osteotome method. It allows gentle bone condensation as an optimum preparation for the insertion of all commonly used implants and can also be used for bone spreading treatments when narrow bone ridges have to be expanded to create a sufficient implant site. Details such as the clearly labeled sizes and depth marks of the Spread-Condense screws facilitate the work of the operator.

Born in 1964, Dr. Hermeler obtained his license to practice dentistry and received a doctorate in 1988 at the Westfälische Wilhelms University in Münster, Germany. In 1991, he opened his own dental office in Rheine. He has authored several articles on aesthetic dentistry, bleaching, endodontics, and implantology and is a member of the German Society for Oral Implantology.

Copyright © 2010 DrBicuspid.com