A new responsive coating for implants may improve their integration into bone and prevent rejection, according to a new study by European researchers.

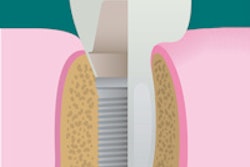

The success of dental implants depends on integration into adjacent bone tissue. Gels made by modifying hyaluronan, a large biological molecule, can be used to coat implants.

Now neutron scattering experiments at the Institut Laue-Langevin (ILL) in Grenoble, France, have shown how a protein that promotes bone growth binds to the surface of implants and can be released in a controlled way.

The study by researchers from Uppsala University and ILL, published in Advanced Engineering Materials (April 1, 2014), shows that the coated titanium surfaces can bind protein molecules. These can be released slowly once the surface comes in contact with a solution of calcium ions, stimulating bone growth on the implant.

The gel layers, a few millionths of a millimeter thick, were characterized using neutron reflection at the ILL, a technique that provides a detailed picture of what happens at a surface.

The research team showed that the protein BMP-2 was bound to the gel, and demonstrated that the protein layer was stable in water but could be released slowly by adding solutions containing calcium.

The research group has now launched trials of similar materials for metal implants in rabbits in collaboration with the Swedish Agricultural University in Uppsala, providing a step toward transferring the technology to clinical applications.