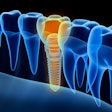

EnBio has launched a new hydroxyapatite surface for implants, OsteoZip, intended to enhance the osseointegration of dental and orthopedic implants into host bone tissue.

OsteoZip is "applied and enabled" by EnBio's CoBlast surface modification process, the company said. The CoBlast process is noncomplex, room temperature, and requires no wet chemistry. Rather it is a novel variation of grit blasting, and the CoBlast processing equipment is a modified version of standard grit-blasting equipment.

EnBio's in vitro and in vivo testing shows that the OsteoZip surface exhibits superior bone fixation and faster osseointegration than other standard implant surfaces, such as roughened, soluble blast media and plasma-sprayed hydroxyapatite, according to the company. The enhanced performance is due to the fact that the hydroxyapatite on the OsteoZip surface is almost 100% crystalline and the thinness of the noncontiguous hydroxyapatite layer (approximately 10 micrometers), EnBio said.

This thin layer -- incorporated into the metal oxide -- guarantees that the hydroxyapatite will not shear or delaminate, unlike traditional hydroxyapatite coatings applied via plasma spraying, according to EnBio. The company expects that this will also result in better long-term stability.

EnBio is offering to either help other companies set up the CoBlast technology, or provide the OsteoZip coating for companies that don't want to do it themselves. EnBio has filed an OsteoZip master file with the FDA, which can then be used by potential clients.

Copyright © 2009 DrBicuspid.com