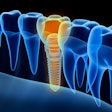

Looking back at the 2009 International Dental Show (IDS) in Germany, there was an abundance of novelties, some of which had already been presented at the Chicago Dental Society Midwinter Meeting and elsewhere. Among all the new products, however, dental implants attracted the most attention. Cone-beam technology, especially in the context of implants, also garnered a fair amount of interest at the show.

More than 200 implant systems are now on the market. At present, zirconia implants are attracting more attention in Europe than in the U.S. They are said to be more biocompatible because the e-modulus is similar to that of the jawbone, and fewer components can corrode than in titanium implants. In addition, zirconia does not conduct electricity, which is important to electrosensitive patients, so there is no interaction with other dental materials already present in the mouth. Surface morphology equal to titanium appears to have been established in different ways.

Up to now, zirconia implants have been available only as single-step systems, which has limited their application in comparison to titanium implants. But these five two-step zirconia implant systems -- all on display at IDS -- are expected to roll out in Europe this year:

|

| The Zeramex ceramic implant system from Dentalpoint. |

Zeramex from Dentalpoint is the first ceramic implant system for which a multiyear clinical study will be carried out at the University of Freiburg in Germany, according to the company. The connection between the cylindrical opening of the implant and the abutment using Panavia cement makes the Zeramex almost as stable as a one-piece system, Dentalpoint said.

The zit-vario-z implant from Ziterion features a tapered connection between implant and prosthetic components, without any microgap and without the risk of micromovements, thanks to a built-in platform switch and an antirotation lock. First results of the mechanical tests indicate an extremely high resistance to fracture exceeding the figures for comparable titanium implants by nearly a factor of three, according to the company. Market introduction is scheduled for the end of 2009, following the completion of a clinical pilot study. Development of this product was part of a Bavarian government-supported medical engineering high-tech offensive, company officials noted.

Creamed Creative Medizintechnik and Maxon, a German company experienced in developing and producing precise technical components using high-performance ceramic materials, have teamed up to produce zirconia implants that have an etched surface pattern and a conical abutment glued into the implant body. To manufacture the zirconium oxide ceramic dental implants, Maxon uses ceramic injection molding technology, which is unique among the newcomers to this market.

General Implants claims to achieve a hydrophilic surface for optimal osseointegration using a nonionizing, electromagnetic irradiation procedure. The company's abutments are attached using a screw, similar to their titanium implants. Scientific research was done in conjunction with Tokyo University in Japan.

HZI-Implant from BPI Systems is a self-cutting cylindric zirconium oxide implant with a nanostructured, hydrophilic surface featuring three apical cutting edges, according to the company. The patented Easyfit structure connection is guaranteed rotation-free and reliably avoids screw loosening, according to BPI. The pediment structure allows direction-independent mold separation and automatic positioning of all system structures, thus ensuring reliable impressions and easy platform switching without the need for additional x-ray examinations, company representatives noted. The zirconia abutments feature a titanium core to yield an allegedly bacteria-proof, tight, gapless fit when screwed into place.

|

| The new zirconia implant from Creamed Creative Medizintechnik. |

Screwless titanium implants

|

|

The Heraeus Kulzer IQ:NECT screwless titanium implant system. |

In addition to the new zirconia products, IQ:NECT from Heraeus Kulzer -- the first screwless titanium implant system with a unique clip mechanism -- also attracted much attention at IDS. The solid abutment has no restricting screw channel and can therefore be processed like a conventional crown. The unique connection technology converts the implant and abutment into a quasi-monoblock unit that combines the advantages of a one-part implant system with those of a two-part system, according to the company.

Each IQ:NECT system component consists of a self-centering clip mechanism to maintain proper positioning, eliminating the need for additional x-rays. A microbiologically optimized internal connection is achieved by gluing the abutment into the implant using the Heraeus IQ:NECT Cem fixing material. A precision applicator is used to dispense the exact volume of Heraeus IQ:NECT Cem needed.

The IQ:NECT was developed at the University Clinic in Aachen, Germany, and tested in numerous studies, according to the company. While the implant system has been on the market since 2005, Heraeus introduced several additions to the line at IDS 2009, including a zirconium oxide abutment comprising a titanium platform and a ceramic cap made of zirconium oxide supplements, and a universal abutment for all-ceramics.

Carlheinz Swaczyna was a general dentist in Krefeld, Germany, for 30 years before retiring in 2007. He writes regularly for the weekly German dental publication DZW - Die Zahnarztwoche.

Copyright © 2009 DrBicuspid.com