The future of dentistry is digital, and the technology is not limited to computerized patient management and digital x-ray systems. It includes 3D intraoral scanners and 3D printers too.

"Digital impressions from 3D intraoral scanners and design files of appliances and prosthetics from dental CAD software is the next step to having a completely digital record and treatment system," said Sam Wainwright, a dental product manager at Formlabs.

Why would a dental practice want a completely digital record? It's easier and more affordable than ever before, and digital records also streamline patient treatments and improve care, according to Wainwright and several other experts.

Christien Kopas of Schell Dental Ceramics in Kelowna, Canada.

Christien Kopas of Schell Dental Ceramics in Kelowna, Canada.Christien Kopas, a digital implementation specialist at Schell Dental Ceramics in Kelowna, Canada, is one such expert. She likens intraoral scanning to a cellphone.

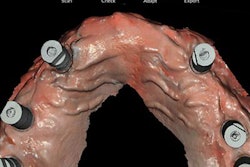

"When the cellphone was launched, it was used as a phone," she said. "Now, your cellphone monitors your sleep patterns and takes a 3D scan of your face. Similarly, when first launched, the intraoral scanner was used to send scans to a lab for more precise restorations. Now, the intraoral scans are full color. The scans can be used for chairside smile design, to discuss the patient's periodontal issues, to plan for implant placement, and for quick turnaround restorations."

Expanding a dental practice into a new area may sound expensive, but gone are the days when 3D intraoral scanners were costly and challenging to use.

"There are a handful of amazing digital impression systems on the market that are miles past those early devices," Wainwright said. "These cutting-edge 3D cameras are still pretty expensive, but they are significantly faster, easier to use (and have in your mouth), and have file and case management software that can connect into almost any downstream digital process, like sending to an external laboratory, design center, or in-house lab with 3D printing or milling."

How practices can use intraoral scanning

There are many uses for an intraoral scanner. One of the most valuable applications for general practitioners is quick turnaround for crowns, according to Kopas.

Digital impressions for crowns can be sent to a lab and designed the same day versus in the past when it could take two weeks. And the faster turnaround that oral scanners and 3D printing provide reduces the negative effects a temporary crown may have on the patient's mouth, which includes pushing the teeth apart or overeruption of the opposing tooth. Further, an oral scanner virtually eliminates remakes, Kopas added.

Dr. Marty Jablow, dentist and chief development officer of Cellerant Consulting Group.

Dr. Marty Jablow, dentist and chief development officer of Cellerant Consulting Group.Dr. Marty Jablow, a dentist and chief development officer of Cellerant Consulting Group, agrees that turnaround time is a primary benefit associated with intraoral scanning and 3D printing. Another benefit is agency.

"Taking a scan and then designing the prosthesis is totally under the dentist's control," Jablow said. That control means dentists can ensure proper fit and function themselves without relying on an intermediary.

By using intraoral scanners and 3D printers, dentists can not only create crowns but also design their own surgical guides, night guards, clear aligners, and patient presentation models. However, dentists don't have to take charge of every aspect themselves.

"They can enlist the help of a dental lab to facilitate the designs and printing, or they can teach their dental team members to do a lot of the heavy lifting," Kopas said. "Training a dental assistant to design a night guard or prepare a case for implant planning allows the dentist to approve and finesse the final designs and QC [quality control] the final product."

Overcoming roadblocks

For practices that may be nervous about using intraoral scanning and 3D printing, Wainwright offers this advice: Consider what might be required to produce these 3D-printed parts and start simple until your comfort levels increase. For instance, a crown requires more working time and complex dental CAD software than producing a patient presentation model or a night guard.

Sam Wainwright, dental product manager at Formlabs.

Sam Wainwright, dental product manager at Formlabs."If you are not an early adopter and not sure where to start, begin with the fundamentals and foundation first, like good digital patient systems with modern computers and servers, then a 3D intraoral scanner to capture digital impressions, and finally in-house production of the basics and primary needs using 3D printing," he said.

Training is also vital. "Using CAD/CAM design software does have a learning curve," Jablow said. "Take some time to become proficient; 3D printing is not 'plug and play.' "

"Learning a new skill takes time, and excellent training is the first step," Kopas added. "A full day of training begins with images of good and bad scans of crown preps, full arch scans, and dentures. Dentists and dental teams need to understand and become familiar with the difference between digital impressions and PVS [polyvinyl siloxane]."

After training is complete, the dental practice doesn't have to be left to its own devices. Offsite support by a dental lab will help the practice transition to using the equipment on its own.

"At Schell, new digital users send their cases to the lab to be reviewed while the patient is still in the chair until they [clinicians] are comfortable with the data required for the best restorative outcome," Kopas said. "This allows the team to become proficient quickly with the least amount of disruption for the patient."

However, that time savings happens only if the dentist isn't doing all the work solo -- it's better if the practice can hire someone part time, ideally a candidate who has CAD/CAM experience, Wainwright said. Yet, what really counts is having someone who is excited to learn and do the work.

"Technical experience is important, but willingness is paramount," he added. And that willingness translates into a return on investment because, as Kopas put it, "training a dental team member enhances their career and allows the dentist to free up their schedule for more productive procedures."

The increased use of digital dental equipment may seem swift, but it also makes complete sense, according to Wainwright.

"It's not a coincidence," he said. "We are at the point where there is such clear value in these technologies at a price that allows almost any dental business to get into it with much less risk."