When it comes to fitting a restoration, the combination of an intraoral scanner and a CAD/CAM system offers a simplified production process compared with the conventional impression technique. But do restorations produced in this manner offer a comparable result to those produced using the conventional method?

That is the question researchers from Austria and Switzerland sought to answer in a study published in BMC Oral Health (December 8, 2016). They undertook an in vitro study to see if there were differences between the techniques in marginal fit. They also asked if the techniques produced restorations that fit within limits of clinical acceptability.

"The marginal fit in restorations is of utmost importance for their quality and longevity, and was one of the main initial concerns of the CAD/CAM systems," the authors wrote.

The study was led by Rinet Dauti, who is affiliated with the department of conservative dentistry and periodontology at the Medical University of Vienna in Austria.

Precise measurements needed

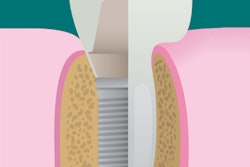

Precise measurements are prerequisites for accurate casts and fitting of restorations. A practitioner has the option of using a conventional technique with any number of impression materials or a digital impression technique. A marginal gap of between 50 µm and 100 µm is considered to be technically feasible, and larger gaps could lead to periodontal inflammations, secondary caries, and cement dissolution, the authors noted.

“The marginal fit in restorations is of utmost importance for their quality and longevity, and was one of the main initial concerns of the CAD/CAM systems.”

The researchers sought to determine if the marginal fit of cemented zirconia copings manufactured after digital impression with the Lava Chairside Oral Scanner C.O.S., version 3.0.2 (3M ESPE) was comparable to zirconia copings manufactured after conventional impressions with polyvinyl siloxane.

They replicated a prepared typodont tooth (#36) 40 times with a vinyl silicone and precise model resin. These teeth were divided randomly into two groups: digital or conventional impressions. The researchers took digital impressions with the Lava Chairside Oral Scanner.

Conventional impressions were taken with a polyvinyl siloxane impression material (Imprint II Garant, 3M ESPE) in a one-step technique using individual trays fabricated with cold-curing material (SR Ivolen, Ivoclar Vivadent). Zirconia copings were manufactured and cemented with zinc oxide phosphate cement.

The researchers cut the specimens in half, with half evaluated with an optical microscope, and the other half evaluated with a scanning electron microscope. They measured the marginal gap and the absolute marginal discrepancy mesially and distally on each slice. The study included a total of 292 measurements.

The researchers found no significant difference in the marginal parameters between the groups, as the table below illustrates. As the mean marginal gap values for both groups was less than 100 µm, the margins were clinically acceptable, they concluded.

| Comparison of measurements in impression group | ||||

| Marginal gap | AMD* mean values | |||

| Measurement method | Optical microscope | Scanning electron microscope | Optical microscope | Scanning electron microscope |

| Digital group | 96.28 µm (± 43.21 µm) |

99.26 µm (± 48.73 µm) |

191.54 µm (± 85.42 µm) |

211.6 µm (± 96.55 µm) |

| Conventional group | 94.84 µm (± 50.77 µm) |

83.37 µm (± 44.38 µm) |

158.60 µm (± 69.14 µm) |

152.72 µm (± 72.36 µm) |

Acceptable gaps

The authors noted that they found it difficult to compare the results of this study with recent published studies because of differences in measuring techniques and measuring parameters. They also noted that, since this study was done in a laboratory, the influence of patient factors, such as difficulties with subgingival preparation margins, blood and saliva contamination, and patient reaction to the impression technique, were not taken into account.

However, both the digital impression and convention impression techniques were acceptable choices for practitioners, they concluded.

"Copings manufactured after digital impression with Lava [Chairside Oral Scanner] show comparable marginal parameters with the copings manufactured after conventional impression with polyvinyl syloxane," they wrote.