|

In order to succeed and thrive in the newly digitized world of dentistry, dentists will have to embrace this new technology. The possibilities are endless within the digitized world. Intraoral scans can transfer a digital impression from the operatory to the dental laboratory in seconds. Communication among all can be nearly instantaneous. Of course, there are challenges in adopting a new technology: new equipment to use, new procedures to follow, and new skills to learn. This technology is continually evolving and will be reported on in future issues. This issue of THE DENTAL ADVISOR (November 2008, Vol. 25:9) introduces CAD/CAM dentistry, from basics to the complex, featuring relevant and timely information on chairside intraoral scanners, chairside CAD/CAM, digital workflow, outsourcing, tooth preparation guidelines, and more. CAD/CAM is an acronym for computer-aided design/computer-aided manufacturing. The CAD portion of the process involves the use of a scanner to create a digital model of the preparation, and sometimes the adjacent and opposing dentition. Once the model has been generated on a computer workstation, the restoration can be designed by the doctor or a lab technician. The CAM portion of the process involves the use of a mill or special printer to fabricate what was designed during the CAD process. This could be a coping, the final restoration or a working physical model.

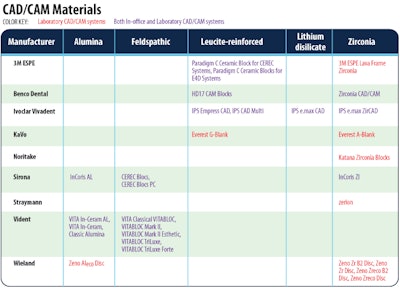

Product Comparison Chart (Click link below to view)CAD/CAM Materials CAD/CAM in the Dental Office

In-office CAD/CAM systems allow the dentist to take a digital impression and design the restoration, all in the doctor's office. Once the restoration has been milled, it is often polished or glazed before placement. Another approach is to send the scan or digital impression to the laboratory. A laboratory technician designs the restoration on the computer and communicates that to the milling machine. The milling machine can be in the lab or outsourced to a milling center. Once the milling machine has completed the restoration, it may require layering porcelain and staining and glazing. CAD/CAM in the Dental Laboratory

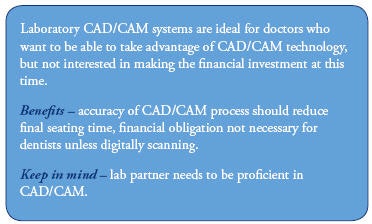

Laboratory CAD/CAM systems can be standalone systems that allow dental laboratories to scan, design, and mill restorations; alternatively, restorations can be outsourced to a milling center where a coping is made. Laboratory CAD/CAM systems may also accept intraoral scans from dental practices and fabricate the final restoration. Digital Impressions

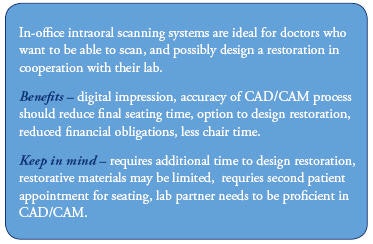

An intraoral or chairside scanner captures digital images of the mouth to build a virtual 3D model of the preparation and adjacent teeth on the computer. These scanners use digital images to help design the restoration. Some scanners require the use of powder or scannable bite registration material. Benefits

Ancillary Materials Required for Digital Scanning

Due to the capturing process, some scanners require the use of a contrast medium or scannable bite registration material. These materials treat the surface being scanned, preventing reflective voids and providing optimal anatomy and margin detail.

CAD/CAM System Configurations

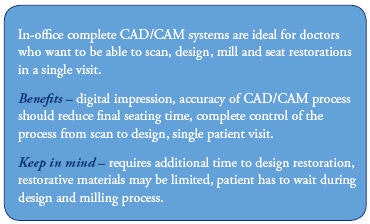

In-office Complete CAD/CAM Systems - Chairside Intraoral Scan and Mill These systems allow the dentist in one patient visit to:

CEREC (Sirona)   In-office Intraoral Scanners - Chairside Intraoral Scan and Outsource Milling These systems allow the dentist to:

Final steps to complete restoration:

Lava Chairside Oral Scanner C.O.S. (3M ESPE)

Laboratory CAD/CAM Systems Laboratory CAD and Laboratory CAD/CAM systems:

Cercon (DENTSPLY Ceramco)

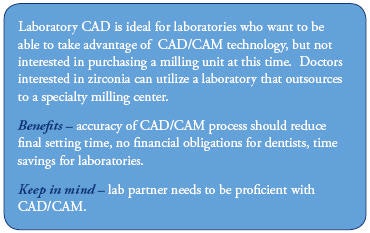

Laboratory CAD Some laboratories have made the investment in digital scanning and design technology. However, to complete the restoration, the lab will outsource the design to another company to mill. Send the restoration back to the design CAD lab for finishing, if applicable. Authorized Lava Milling Center (3M ESPE)

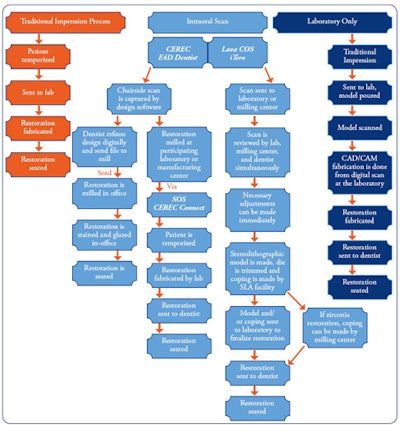

CAD/CAM Workflow

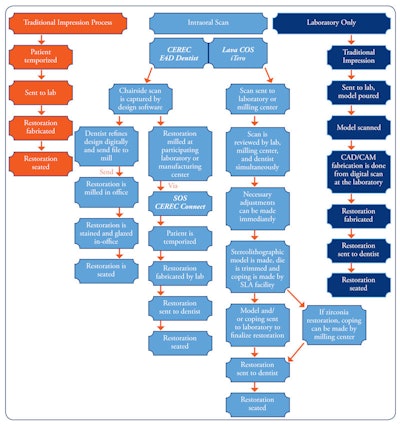

CAD/CAM workflow is a series of steps that involve the dentist, dental laboratory, and at times, milling center. The diagram below provides the options on how information is transferred to create a complete restoration (click to enlarge).  Material Options in CAD/CAM

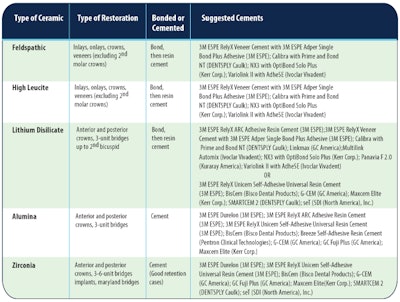

See CAD/CAM Materials table at top of article. All-Ceramic Restorations in CAD/CAM

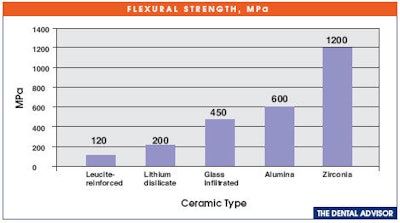

These are the ceramics used in dentistry for the last 30 years and their respective flexural strengths. Zirconia is the strongest of these ceramics.

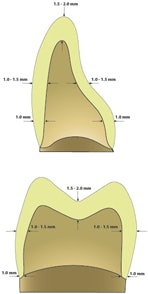

Tooth Preparation Guidelines for All-ceramic Restorations

How to prepare a tooth

Preparation is critical

Tooth Preparation Illustration (Click on the image for a larger view.)  Cementation and Bonding of All-Ceramic Restorations

Summary

CAD/CAM dentistry is changing on a daily basis. Every part of the dental profession can get involved in some way. The future is promising in terms of the technological advances that CAD/CAM is providing to the dental industry. Future issues will focus on the integration of 3D imaging, laboratory involvement, the evolution of new materials and equipment, and exciting restorative options. Requests for reprints should be directed to The Dental Advisor. |