3D printing technology is battling to convince surgeons that it is a financially viable treatment for craniomaxillofacial (CMF) reconstruction, according to an analyst with research and consulting firm GlobalData.

The lack of insurance coverage for patient-specific implants and insufficient reimbursement for complex trauma cases are deterring many CMF surgeons from participating in medical training for using presurgical planning and 3D-printed implants, explained Linda Tian, GlobalData's analyst covering medical devices.

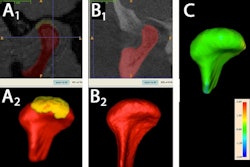

These concerns were also raised by Oxford Performance Materials, makers of the OsteoFab patient-specific facial device (OPSFD), a 3D-printed polymeric implant for cranial and facial indications recently approved by the U.S. Food and Drug Administration (FDA).

Tian described the processing chain, from data acquisition to 3D printing of CMF patient-specific implants, as practical and uncomplicated, but 3D printing might continue to be plagued by a major weakness in terms of its future growth within the orthopedic industry, namely the need for hospital administrators to cut costs associated with high-volume surgeries, such as trauma.

While 3D-printed implants may theoretically reduce the overall cost of facial implant ownership by reducing the operating time, hospital stay duration, and chance of procedure complications, there is a lack of clinical evidence suggesting the actual cost-effectiveness of 3D-printed implants in CMF surgeries, she noted.

GlobalData expects that Oxford's OsteoFab approval will lead to a further rise in the utilization rate of custom-made devices for midface reconstruction, mandible reconstruction, orthognathic surgeries, and possibly expanded indications.