3Shape has introduced the CAMbridge 2010 for the dental lab market. The system is designed to automate the gap between dental CAD designs and manufacturing, according to the company.

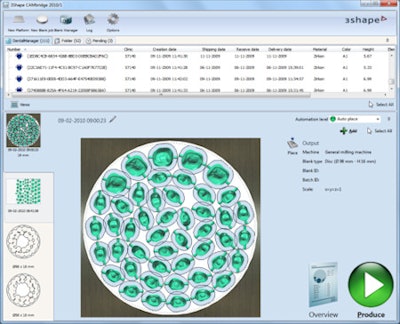

One of the key advantages of the CAMbridge 2010 is its ease of operation and automation, which speeds production, Henrik Vestermark, 3Shape's vice president of business development for North America, noted in a press release. For example, the system can automatically place 51 units in a 98-mm blank within 30 seconds, according to the company.

"We integrated CAMbridge with our new Dental System 2010 so jobs can go directly into CAMbridge, which then automatically prepares the blanks for milling -- including placement, adding drops and spruces, and calculating the necessary tool paths," Vestermark said.

CAMbridge 2010 also supports non-3Shape-generated stereolithography (STL) files and takes full advantage of dual or quad core processor technology for the fastest production speed, the company noted. The system also includes a blank management database to track the path of each blank for optimize material use and reduce production costs. Users have the choice of working in conjunction with third-party CAM software or generating the complete tool paths within CAMbridge 2010.

|

| The CAMbridge 2010 system by 3Shape. |

Copyright © 2010 DrBicuspid.com