3D printing, also known as additive manufacturing, is omnipresent in dental laboratories globally. In this vastly digital world, the production of dental prostheses and appliances has undergone a transformation driven 100% by digital processes. Instead of a plastic bag with an impression as the starting point, the dental lab is now receiving a digital file from the cloud. From these data, the final prosthesis or appliance must be manufactured.

Goodbye, plaster room. Hello, computer and 3D printer.

Digital processes also have a positive impact on the communication and relationship between dentists and technicians. Instead of a handwritten lab slip with short instructions tossed in the box with the impression, the technician has much more information available and can communicate with the dentists using visual aids that are not available in the analog world.

The impact of digitization in dentistry seems to have another effect that might become more visible in the future. Dental offices implementing more digital processes can benefit strongly from the presence of a dental technician in the building. If implemented correctly, this addition can reduce treatment times tremendously due to more efficient communication and resource allocation as well as reduced logistics requirements.

Harmonizing precision: Bringing lab technicians into dental offices

The concept of dental technicians working in a dental practice is not new. In fact, in Germany for example, the concept of praxislabor -- a dental laboratory owned by and located in a dental office -- is becoming more commonplace.

However, the in-house technician referred to in this article is not completely the same. With the trend to bring digital dentistry solutions into the dental practice, this necessitates having someone on staff who possesses the skills and expertise to effectively operate the equipment. In many cases, dentists will rely on dental assistants for such tasks, but this doesn't yield the same benefits as having a trained digital lab technician available.

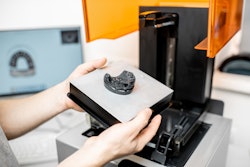

While digital dentistry solutions streamline the production of patient-specific devices such as crowns, dentures, and nightguards, the entire process requires involvement from a highly trained expert. While making a mold of a patient's mouth has been overtaken by digital impressions using a 3D scanner, the resulting digital file can't be immediately sent to the 3D printer for production.

There is additional work that needs to be done to the file to optimize it. Additionally, 3D-printed devices don't come right out of the printer ready to be inserted in a patient's mouth.

Before the dentist can use a device for patient treatment, a few more actions are required to post-process the device to make it patient-ready. Having a dental technician who can optimize the patient scan, initiate the print jobs, and finish the appliances has a significant, positive impact on the timelines and quality of the treatment.

The benefits of in-house lab technicians include the following:

- Enhanced collaboration between clinicians and lab technicians results in improved communication for better treatment outcomes.

- A streamlined workflow enables real-time feedback for rapid iteration on device designs while in-house oversight of the production process, including quality control, yields faster issue identification and resolution.

- Supply-chain control mitigates risks to delivery time, reduces costs required for transportation, and benefits the environment due to fewer logistics requirements.

- An improved patient experience due to fewer required visits for scans and fittings and the availability of quality provisional restorations during the same visit, ultimately minimizing the impact of dental procedures on a patient's life.

This trend of in-office technicians is already in practice with clinicians, including Dr. Roxanne Lowenguth with Roc Perio & Implants in Rochester, NY. This periodontal surgical office was an early adopter of digital technology, including going paperless and using digital radiography, cone-beam computed tomography, scanning, and implant planning.

In 2018, the office fully committed to 3D printing becoming part of its workflow. After conducting a thorough evaluation of commercially available printers at that time, the practice selected 3D Systems' NextDent digital dentistry solution.

Dr. Lowenguth and her team fully leveraged their partnership with 3D Systems to integrate the new technology into the office. A technical team of two brothers runs the in-house digital lab. Daily print jobs include occlusal guards, clear retainers, surgical guides, and provisional restorations, including crowns, bridges, and hybrid and full dentures.

With the inclusion of the NextDent digital dentistry solution, Roc Perio & Implants has not only streamlined patient care in its office, but its digital lab assists referral dentists with their printing needs. The in-office digital lab has also added smaller printers to increase productivity.

Strategic considerations for seamless integration of lab technicians and digital dentistry

Digital dentistry solutions are pivotal for modern dental practices due to their ability to enhance precision, efficiency, and the patient experience. However, they are not a one-size-fits-all solution. When integrating digital dentistry into a clinical setting, here are some tips for a successful endeavor:

- Start with the application in mind. When implementing new digital equipment in your practice, think about the target application or applications for which you want to use it. Consider how it can not only benefit creation of the appliance but also the patient. Start small and build on your successes to expand the applications. To maximize investment and outcomes, partner with a solution provider that not only understands the technology but also has deep expertise in dental applications.

- Post-process for success. Always keep in mind that the parts don't come out of a 3D printer ready to put into a patient's mouth. Postprocessing of 3D-printed medical devices is crucial to obtaining biocompatibility and mechanical properties of the final device. There are no cutting corners. These materials will only work if the manufacturer's guidelines are followed.

- Realistically leverage your production workflow. Use your equipment and technician to the best of their abilities, but don't stretch it too far. Your chairside system and team are specialized in efficiently achieving quality provisional restorations. In many cases that means that the direct provided restoration will later be exchanged for a high-end, aesthetic final restoration manufactured by an external lab and a technician who specializes in that. They can often start from the same data that the in-house technician used.

- Invest in relationships. Operating digital dental equipment requires not only deep dental knowledge but also a good understanding of information technology infrastructure, including computers, networks, backup systems, cybersecurity … the list keeps expanding. Leaving all these crucial items to your dental assistant who received an hour of training from the company that sold you the solution will likely not get you the intended results. Therefore, it's imperative to engage in a long-term relationship with the solution provider. Invest in proper training on the systems and make sure to stay up to date. The best maintenance is preventive maintenance. This approach will help mitigate the costs of downtime, patient disappointment, and replanning.

The opportunities ahead

In conclusion, the significance of 3D printing in digital dentistry cannot be overstated. It has revolutionized the landscape by providing a platform for enhanced collaboration and elevating the overall patient experience. This technological advancement allows dentists and dental assistants to dedicate more valuable time chairside with their patients, reinforcing the human touch in dental care.

Simultaneously, it empowers dental technicians to focus on intricate tasks like making plans, designing, and crafting prosthetic appliances, ensuring precision and excellence in every aspect of dental treatment. Embracing digital dentistry and bringing the lab technician into the dental office opens the door to a whole new realm of possibilities for the convergence of innovation and personalized care.

Based in Belgium, Stijn Hanssen has a diverse work experience in the dental industry that began at ES Tooling and, later, Dentsply Implants, LayerWise, Imetric 3D SA, Digiflow 3D, and NextDent. He is currently director, dental applications and business development, at 3D Systems Corporation. Hanssen's roles have included research and development project manager, CAD supervisor, business unit manager, and commercial manager. Connect withStijn Hanssen on LinkedIn.

The comments and observations expressed herein do not necessarily reflect the opinions of DrBicuspid.com, nor should they be construed as an endorsement or admonishment of any particular idea, vendor, or organization.